CWIS Weighbridge Systems

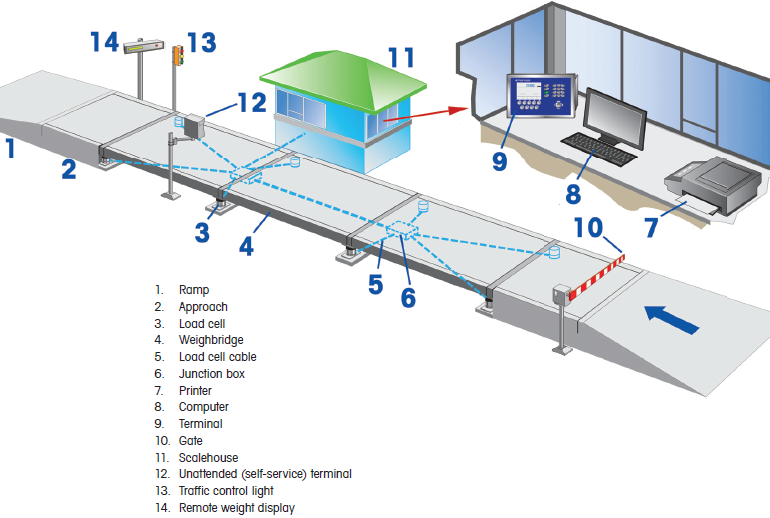

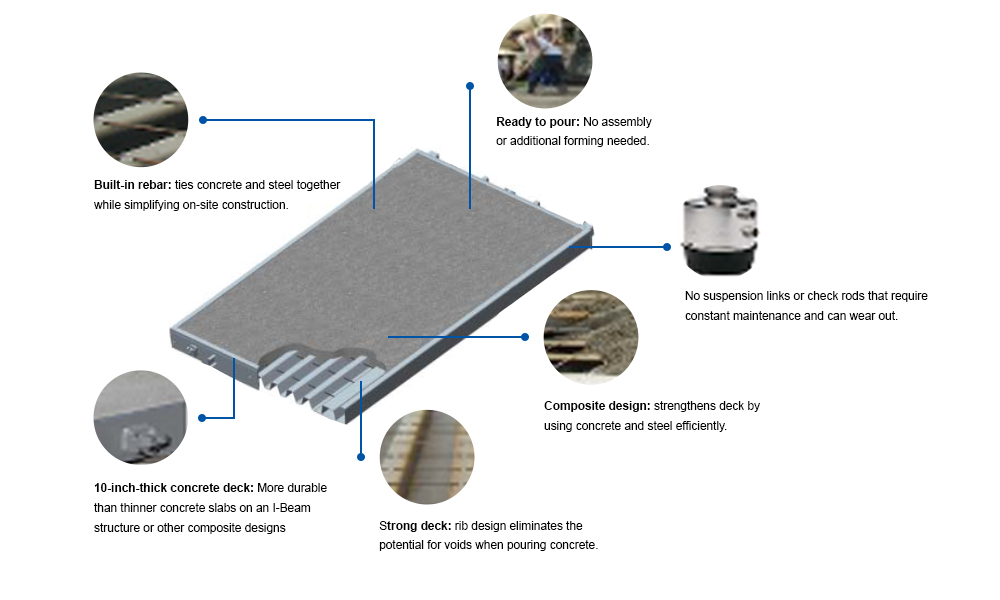

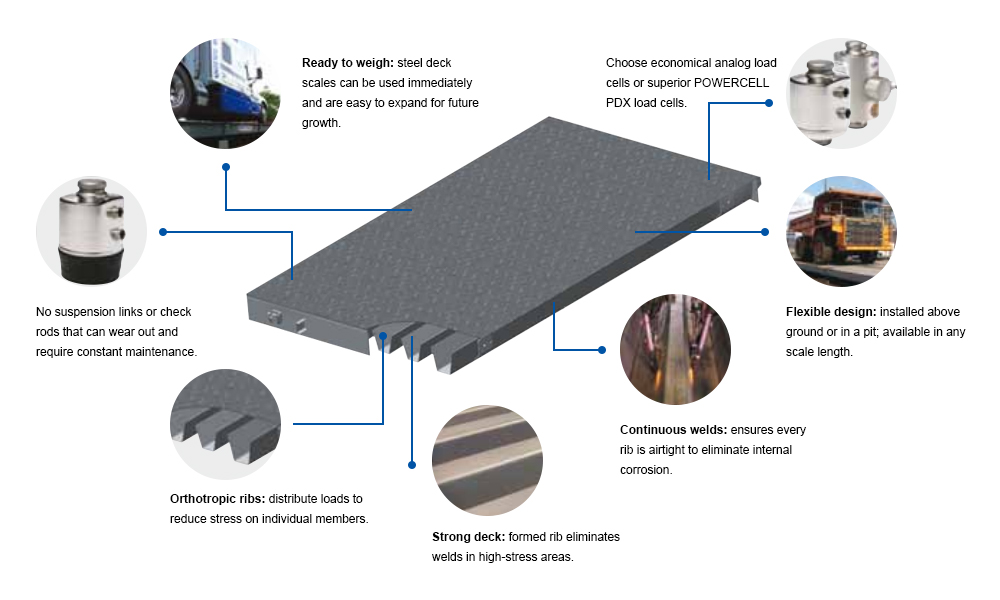

As the Malaysia’s leading Truck Scale / Weighbridge Supplier, CWIS offers a complete range of Truck Scale System for the application of commercial duty to extreme duty cycle. The deck design for the upper surface of the weighbridge is of steel or concrete surface provides equal weighing performance because both are built to the same design specifications. However, there are some differences that could make one deck type more advantages for your site or application.

We offer both Pit-mounted and Surface version (or referred to as Pitless Weighbridge), constructed from steel and steel concrete composite. Surface version can be installed with concrete ramps or steel ramps, making it easier to move the weighbridge to a different location.

We also offer portable type weighbridge, ideal for construction sites.